By investing extensively in advanced production technology, our primary objective is to manufacture the most premium products with unparalleled performance consistency.

The MotherShip™

Connection — NFC.

Enhanced Precision Through Technology

In 2020, The Mothership became the first in the snowboard industry to introduce an NFC system in our snowboards. This chip enables precise tracking of each board's production journey , resulting in higher quality and reduced waste.

Enhanced Experience Through Technology

Beyond the production floor, we have taken NFC capabilities to the next level. Now, you can connect with your board by simply scanning it with your phone . This NFC interface enables you to register your snowboard, streamlining the customer service process and granting exclusive early access to new product information, drops, and CAPiTA team videos exclusively for NFC-registered users.

PLT Topsheet Technology

Unlike the traditional industry model of pressing the topsheet onto the snowboard and using lacquer to hide imperfections, The Mothership utilizes proprietary PLT Topsheet Technology. This innovative technique revolutionizes production by applying flawlessly finished graphics to our snowboards without any telescoping from the fiberglass layers. As a result, our boards are lighter and possess an unparalleled finish quality and graphic depth , setting them apart from the competition in the industry.

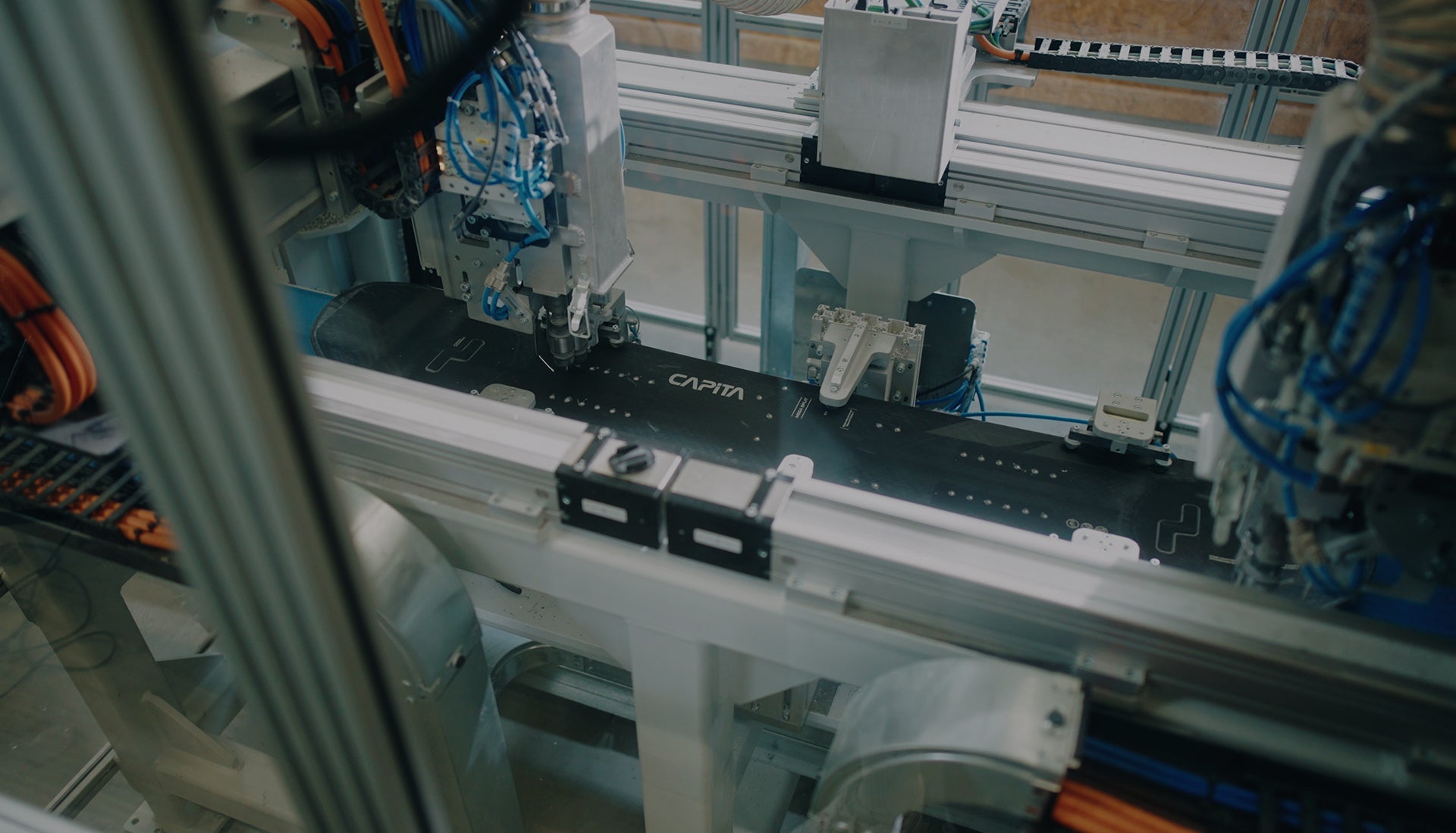

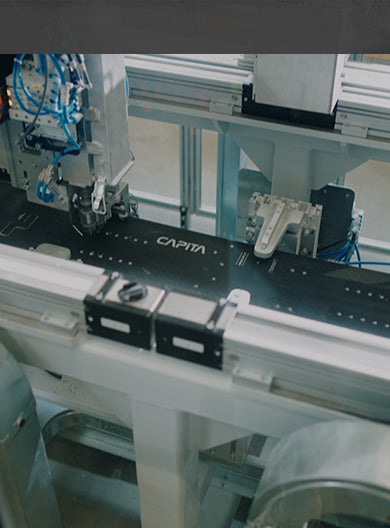

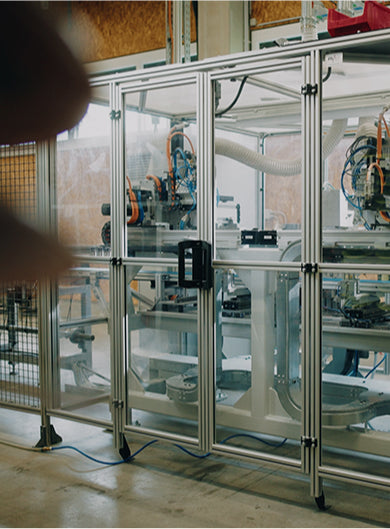

Fully Automated Grinding & Finishing Lines

Our computer-programmed and fully automated grinding and finishing lines meticulously fine-tune snowboards to perfection. This not only minimizes energy consumption and material waste in production but also guarantees the highest premium quality . Additionally, each board undergoes two thorough hand inspections as a final step to ensure exceptional craftsmanship

Thermal Insert Drilling

Unlike other snowboard factories that rely on a human hand and a standard drill for tapping board inserts, which can be prone to imprecision and generate excess scrap, The Mothership stands out with its newly developed automated thermal insert drilling technology. This advanced system utilizes thermal scanning to identify the precise location of each insert and taps them with robotic precision. The result is a precise insert connection that instills confidence in a higher-performing product, guaranteeing a solid binding-to-snowboard connection .